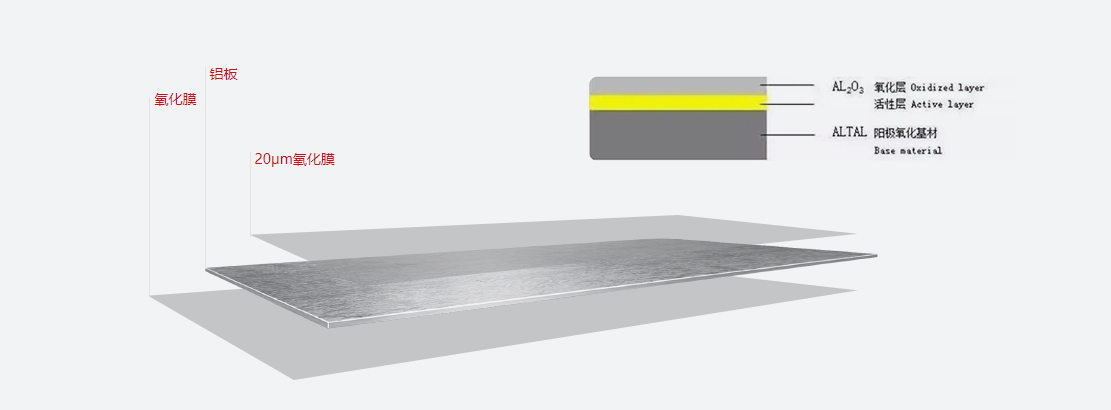

Anodized aluminum plate is the aluminum plate placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, under specific conditions and applied current, electrolytic. A dense oxide film is formed on the surface of the aluminum plate, and the colorless and porous nature of the anodic oxide film is utilized to achieve the purpose of coloring/dyeing and protecting the aluminum matrix.

Aluminum oxide plate is the cathode. Carbon rod, stainless steel plate for the anode. Electrolyte is salt, alternating current. Metal ions adsorbed at the cathode, into the oxide film hole, metal ions in the oxide film hole for a series of electrochemical reaction and color, this coloring method, weather resistance is very good

Electrolytic coloring: single color, strong weather resistance, can be used outdoors. (Aluminum, gold, Champagne gold, bronze, stainless steel)

Due to the adsorption of oxide film, the oxidized aluminum plate is soaked in a certain concentration of dye, and the dye is deposited in the membrane hole. Dyes are classified into organic dyes and inorganic dyes. Organic dyes are very colorful, but the weather resistance is poor, inorganic dyes less color, but the weather resistance is very good.

Dyeing: can produce a variety of toner mix color, color variety.